Your technology partner

with innovative products

and affordable prices !

with innovative products

and affordable prices !

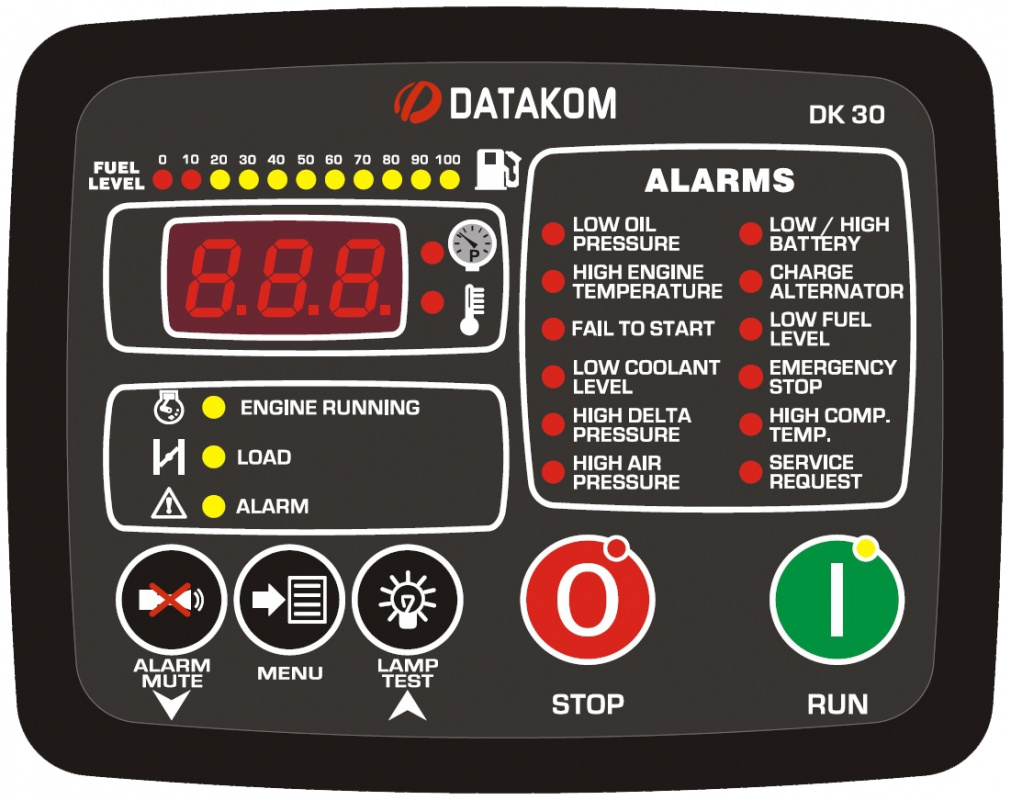

DATAKOM DK-30 Diesel Compressor Controller

* All prices are retail and VAT exclusive

The DATAKOM DK-30 is a high-tech product providing control and protection of diesel engine driven, screw or piston type air compressors. The controller incorporates all functions needed in a compressor control panel. Thus no additional modules are necessary resulting in lower panel cost.

The controller features full engine protection and instrumentation through analog and digital inputs and outputs. It acts also as an overspeed protection relay protecting the engine from overspeeding. In order to prevent battery drain, in STOP mode, the controller turns completely off, consuming zero current. The engine rpm is read through the magnetic pickup sender installed on the engine flywheel.

The “early start” function analyzes the air consumption trend and runs the compressor so that the pressure never falls below the low limit.

In order to have a constant output pressure, the controller is capable of governing the engine speed with its analog output driven by a PID loop. The controller supports multi-compressor application up to 8 compressors. The logic level Modbus RTU communication port of the controller allows computer connection providing monitoring and program parameter adjusting.

The controller configuration may be done through the front panel or using the free PC software. The PC software is available for free download at manufacturer’s website. It is possible to monitor and record the controller using the free RAINBOW+ software.

● Automatic operation via output pressure

● Load solenoid control

● Analog speed control output

● Multiple compressor support

● Comprehensive engine instrumentation

● Detailed engine protection

● Engine overspeed protection

● Zero power consumption at rest

● Flexible engine hours calculation algorithm

● Early start function preventing pressure drop

● History records

● 5 independent service counters

● Magnetic pickup input

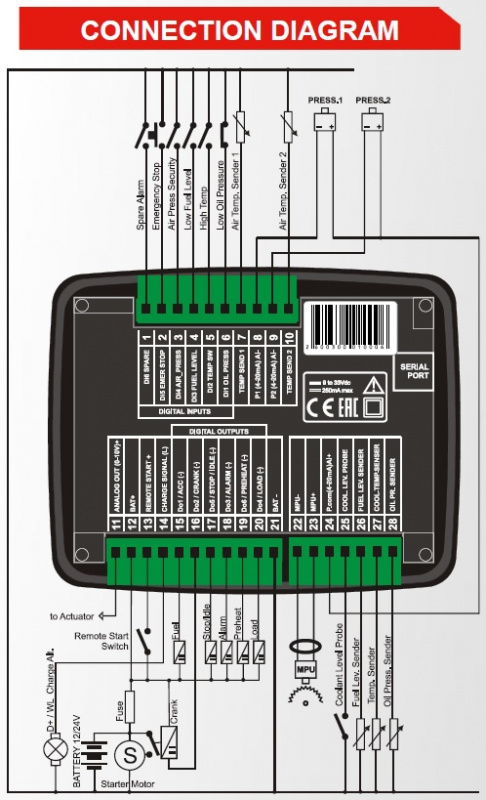

● 6 programmable digital outputs

● 6 programmable digital inputs

● 3 programmable engine analog sender inputs

● 2 air pressure sensor inputs

● 2 air temperature sensor inputs

● Adjustable sensor characteristics

● Logic level serial port

● MODBUS-RTU communications

● Password protected front panel programming

● Low panel depth, easy installation

● Wide operating temperature range

● Sealed front panel (IP65 with gasket)

TECHNICAL SPECIFICATIONS:

DC Supply Voltage: 9.0 to 33.0 V-DC

Cranking Dropouts: Survives 0V for 100ms.

Typical Current consumption: 130mA-DC

Maximum current consumption: 250mA-DC

DC Outputs: Protected mosfet semiconductor

outputs, rated 1Amp@28V-DC

Charge Alternator Excitation: min 2W

Magnetic pickup voltage: 0.5 to 30V-AC

Magnetic pickup frequency: 0 to 10000 Hz.

Digital inputs: input voltage 0 to 30 V-DC.

Connected to BAT+ via internal 47K resistor.

Analog sender input range: 0-5000 ohms.

Pressure inputs: 4-20mA pressure sensor

Temperature Inputs: 1000 to 5000 ohms,

(KTY/NTC/PTC sensors)

Serial Port:

Signal Type: logic levels

Communication: Modbus RTU

Data Speed: 9600 bauds

Operating Temperature: -30°C to +70 °C

Storage Temperature: -40°C to +80 °C

Max. Relative Humidity: %95 non condensing

Protection Degree: IP 65 (front, with gasket)

IP 30 (back)

Enclosure: Flame retardant, ROHS compliant,

high temperature ABS/PC (UL94-V0)

Installation: Panel mounted, rear retaining plastic

brackets.

Dimensions: 132x105x54mm (WxHxD)

Panel Cutout: 116x86mm minimum

Weight: 250 gr

EU Directives:

2006/95/EC (LVD)

2004/108/EC (EMC)

Reference standards:

EN 61010 (safety)

EN 61326 (EMC)

WE DO NOT SHIP THIS PRODUCT TO USA AND CANADA